Solutions, Technology, and Service

for Plastic Manufacturers

the way to success!

Our focus is on an all-encompassing product offering. No one else in the plastic processing industry has you covered as completely as SEScc. We’re committed to what our customers need: focused on providing excellence in pellet-to-part solutions.

Injection Moulding machine

Following years of great success with the Haida “Gotty” machines, we have provenreliability and capability of this machine time and time again. We have forged a strong bond with our supplier and strive to improve on our machines as the industry evolves.

We can offer the machines as Standard and Servo Energy saving. The machine can be custom build and an upgraded PLC and control system as well as closed loop injectionon the Standard machine can be supplied.

Machines range from 88Ton up to 3300T. At the 2015 Chinaplas Exhibition, the machine now has fast injection capabilities with a Servo Full Electric Injection Unit.

Critical and non-critical spares are kept in stock and full technical support is given onsite as well.

Plastic Machine Controller

The ideal injection molding controller for the plastic injection molding process.

The plastic injection industry manufacturers have cultivated a long and stable cooperation relationship between us for many years.

Furthermore, we supply blow molding machine controllers, valve gate controllers, digital temperature controllers, and hot runner temperature controllers related to injection molding machines.

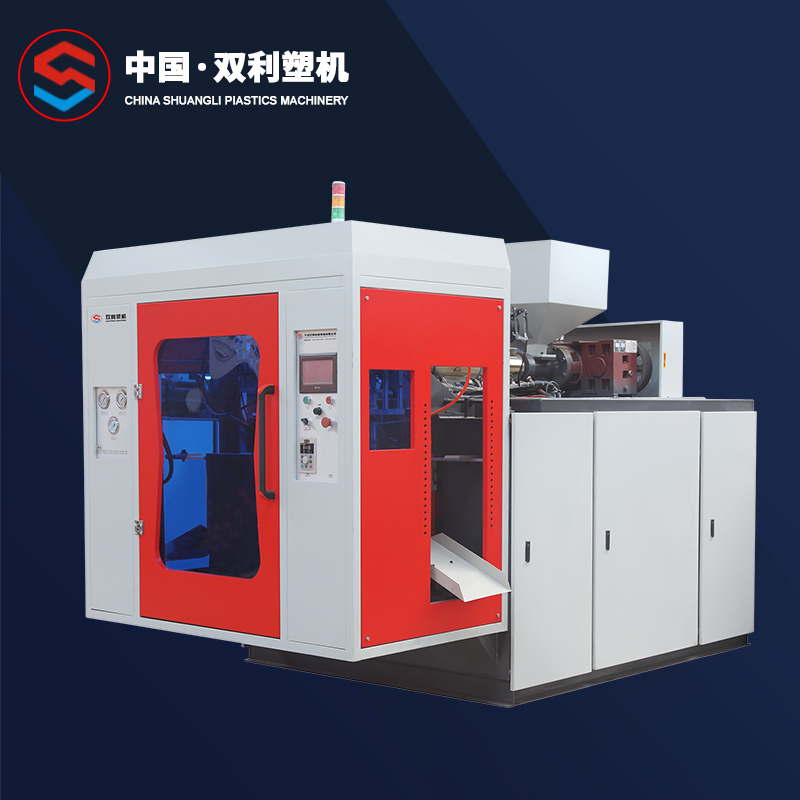

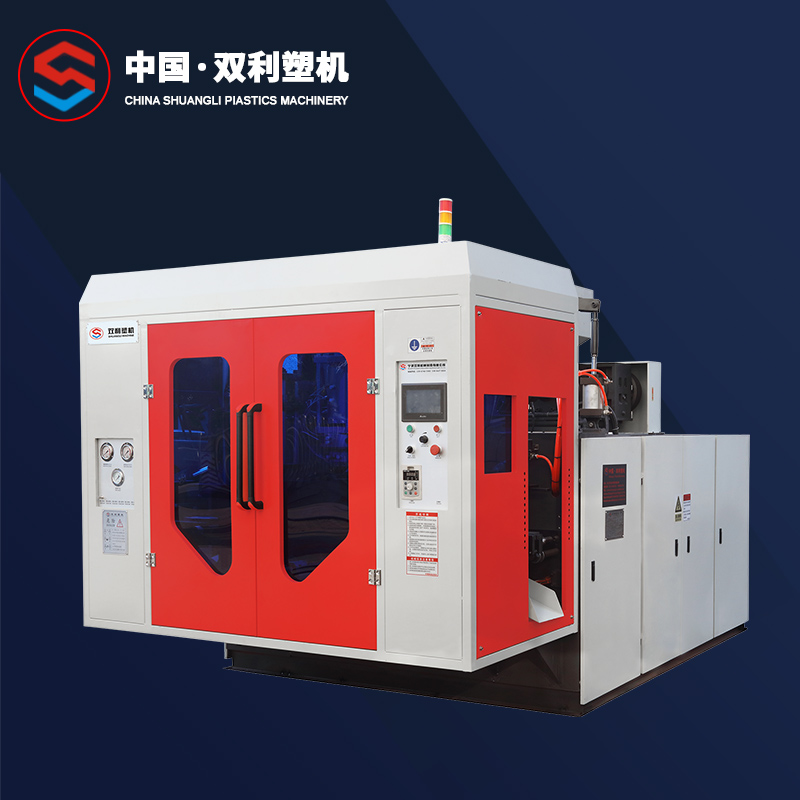

Extrusion Blow Molding Machine

Energy-saving, Efficient, Automation & Standardization

The D series is the industry standard for small blow molding products, including food packaging bottles, lubricant chemical containers, and milk bottles. The machine has a sturdy construction, is simple to use, moves steadily, and is durable.

The triangular beam structure has high rigidity and good stability. Linear guide for barrel movement, low resistance, high precision.

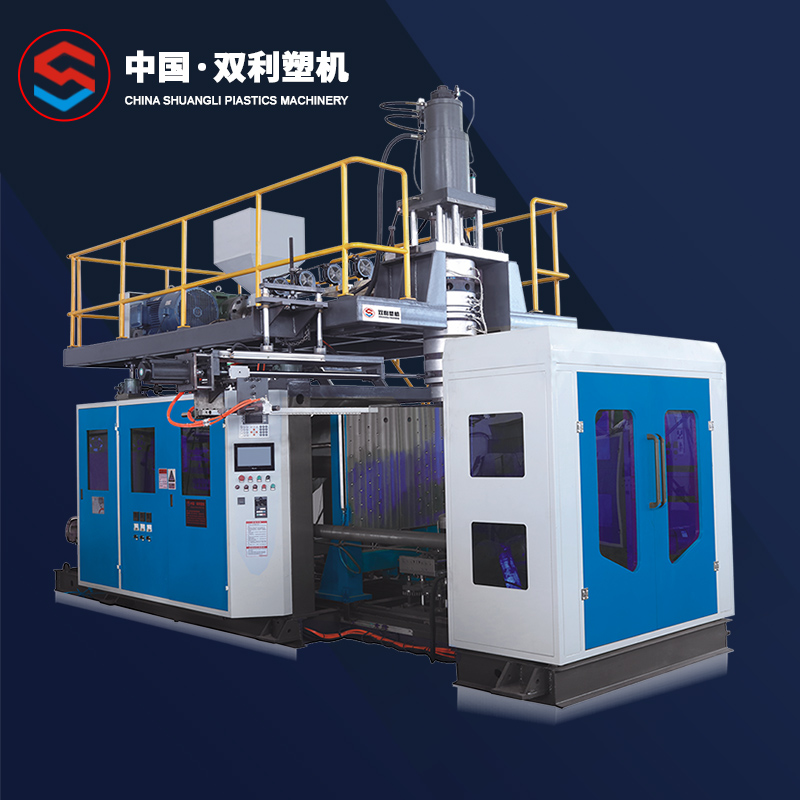

Accumulative Blow Molding Machine

Adopt accumulator die head and timer control.

If it is a large-sized and high-capacity product, you must choose an accumulative head blow molding machine, because such a product takes a long cycle and the material will stay in the screw for a long time

For example, the blow molding machine with accumulator die-head produces complexly shaped products, large chemical drums, IBC tanks, and other large industrial parts.

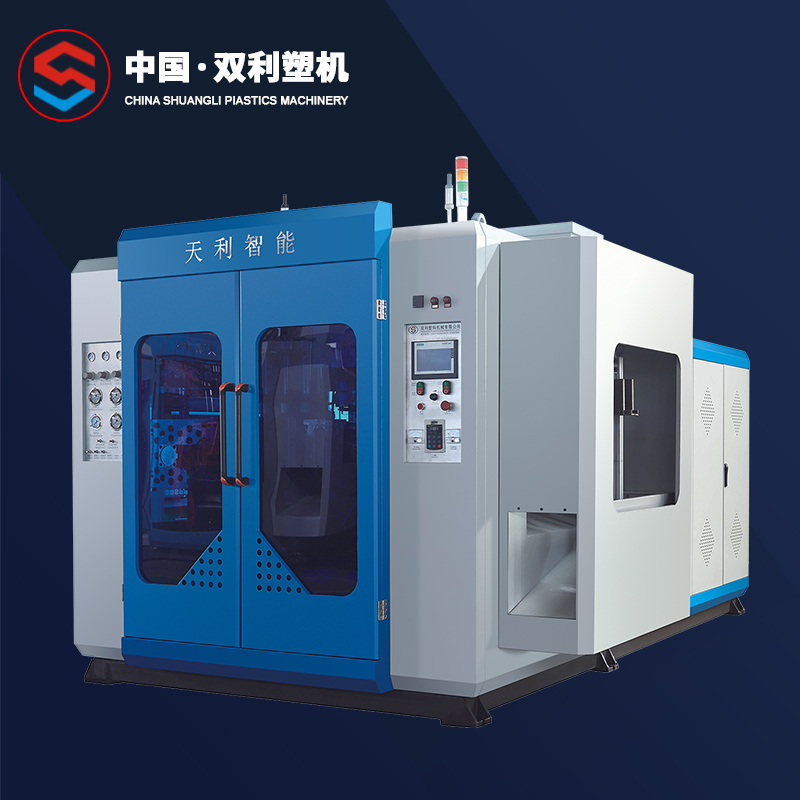

Injection Blow Molding Machine

Automatic and intelligent injection blow molding solution.

Servo drive, energy saving 25-45%.

Large capacity mold installation size for higher output.

Stripping plate overturn pneumatically, safe and clean.

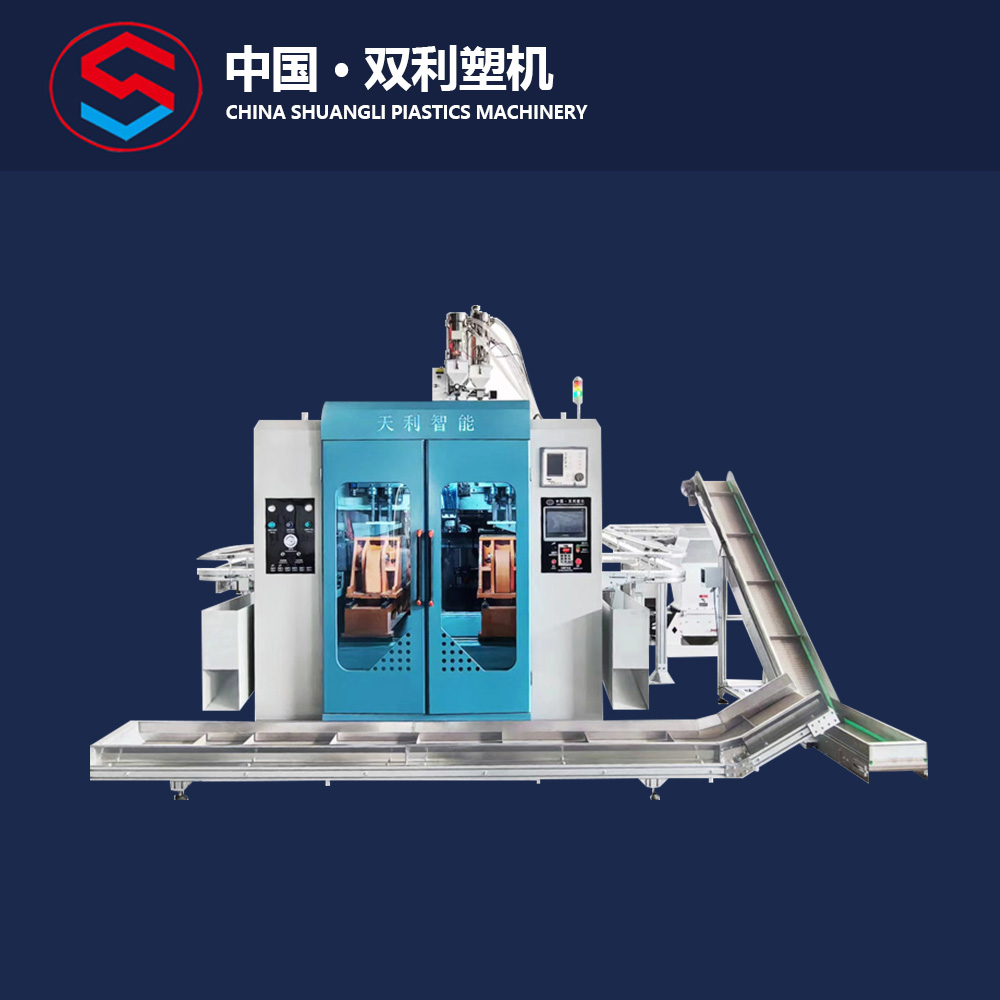

Injection Blow Molding Machine

Accurate and energy efficient

Both injection and blowing stations adopt three cylinder mold locking structure, open and close the mold fast, shorten production cycle with high efficiency.

Servo double oil hydraulic drive system with accurate control, energy saving more than 25%.

The triangular beam structure has high rigidity and good stability.

Linear guide for barrel movement, low resistance, high precision.

Featured products

Leading provider of auxiliary equipment and automation systems for plastic processing.

Click to enlarge image

Chillers

Air-cooled chiller and Water-cooled chiller

Industrial chillers are essential for preserving ideal temperatures in blow molding, extrusion, and injection molding, among other plastic processing applications. Air-cooled and water-cooled chillers are the two main varieties. Knowing the variations between the chillers will enable you to choose the one that will work best for your particular cooling requirements.

-

Air-cooled chiller

- Additional equipment not needed (uses ambient air to dissipate heat)

- Simple and less expensive to install without any additional equipment

- Lower maintenance needs but efficiency can be affected by high ambient temperatures

- Higher cost to run the electric fan

- Not ideal when water supply is limited or concerns for water conservation

-

Water-cooled chiller

- Additional equipment needed (e.g. external cooling tower)

- More complex and costly to install (e.g. cooling tower and plumbing)

- Higher maintenance but generally more energy-efficient and consistent in performance

- Higher initial investment but lower cost to operate the cooling tower in the long term

- Ideal for situations where water supply and conservation are not critical concerns

Drying & Dehumidifying

Performance characteristics

The raw material contact surface is made of all stainless steel material.

Precision die-casting aluminum shell with smooth surface and good insulation performance.

Silent fan with optional air filter to ensure cleanliness of raw materials.

Adopting a pointer/digital temperature controller, it can accurately control the temperature.

Both the barrel body and the machine base are equipped with material viewing windows, which can directly observe the internal raw material situation.

The curved design of the electric heating cylinder avoids combustion caused by the accumulation of raw material powder at the bottom of the cylinder.

The aluminum casting mold is independently designed, with the barrel body flipping backwards, suitable for any robotic arm.

The triangular beam structure has high rigidity and good stability.

Linear guide for barrel movement, low resistance, high precision.

Granulation & Recycling

General Granulator Plastic Bottle Crusher

WSGP is suitable for granulating plastic products including sheets, pipes, profiles, packaging materials, and sprues.

WSGD is suitable forcontainers, thin-walled pipes, blow-molding parts, and bottles.

1:Staggered blades ensure uniform granules with high efficiency.

2:The distance between the rotary and fixed blades is adjustable.

3:Multiple protection functions.

4:General-purpose granulator adopts a sealed bearing which allows high durability.

Feeding & Conveying

WSAL-300G/400G Stand-alone Autoloader For Plastic Pellets

1:Small-sized and lightweight.

2:Controlled by a Microprocessor.

3:Alarms for overloading and material shortage.

4:Featuring a cable controller for easy and quick adjustments.

5:Can be paired with a bag filter for wind.

The 300G model adopts a high-speed brush motor for a smaller footprint and strong suction.

The 400G model adopts a high-pressure blower for less noise and longer durability.

Mold heat

General Granulator Plastic Bottle Crusher

The WSTW/O mold heaters generate and transfer heat to the mold, with the heating temperature ranging from 95°C to 200°C. The heating-conducting medium is available in water or oil.

Feeding & Conveying

WSAL-700G Separate-hopper Vacuum Suction Autoloader

1:Separated design for safety reasons and long-distance conveying.

2:Easy to clean.

3:Stainless-steel materials.

4:Alarms for overloading and material shortage.

5:High-speed brush motor for a smaller footprint and strong suction; suited to convey virgin materials.

6:CE standard certified.

Featured products

Fully automatic blow molding machines.

Click to enlarge image

Plastic machine-fixed open and close mold storage type hollow blow molding machine

Plastic Machine--K-type

Pratt & Whitney Series

Plastic Machine Tianli

Intelligent Pilot Edition Series

Plastic Machine High end

all motor lightning series

SLB-65 small energy-saving automatic bottle blowing machine 5ml-1000ml